Unimat 8

Manufacturer: Plasser & Theurer

Type: Unimat 08-475/4S

Serial number:1287

Date of construction:2007

SRM no:1666208

NVR no: 99 84 942 509-6

unimat 10

Manufacturer: Plasser & Theurer

Type: Unimat 08-475/4S

Serial number:1360

Date of construction:2011

SRM no:1666210

NVR no: 99 84 942 524-3

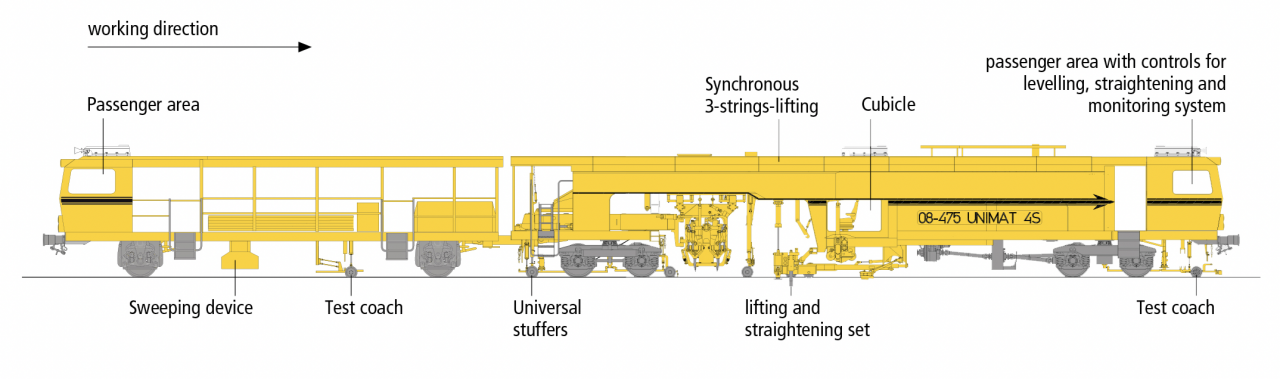

A Switch Tamping Machine

A switch tamping machine corrects the height and lateral position of the track. This part is about a switch tamping machine. Those machines can tamp a turn out and straight track. The correction is done with a combination of lift and lining installation. With this you can lift the track and slide it sideways. With the tamping aggregates the ballast is squeezed under the sleepers. And with a Unimat you can holt one or more aggregates because there are more difficult parts in a switch. The lift and lining installation, tamping aggregates, measuring trolleys for lift and lining and shoulder compactors are also on this machine. The correction height of the track is entered by someone in the front tower. Sometimes the lift and lining displacement entered in advance into the ALC computer. If they do than it’s possible to do the lift and lining displacement with a laser. In the ALC they also enter the details of arches, so that the radius of such a bow will be neatly bent again. The operation of the tamping machine and various other devices takes place in the tamping cabin. The tamping machine is controlled by four people. One in the front cabin and two persons in the tamping cabin and the fourth person is always outside to keep several other things in mind, and he is in control of the broom to sweep the ballast back between the sleepers. Those several other things are things such as cables and helping the stopper with a double beam so that it does not move when you are going to squeeze under the ballast. Communication between each other is going through radios or intercom with outdoor wireless headsets. The video shows the operation of a Unimat. The side compactors ensure that the ballast gets some resistance alongside the sleepers again. With various measuring wheels under the machine the positioning of the track is measured, how the track is positioned in front and rear of the machine. All this is recorded and stored digitally on a kind of printer and a floppy disk or a USB stick, this device is called a DAR. The abbreviation for Data Acquisition Recorder. In Germany, the DAR required on the machine and must be inspected. There should also be a DAR operator present. The operator has to be present during the recording and has the responsibility to judge the recording. On this moment al machines with a DAR get a new digital recorder named DRP (Data Recording Processor) This person has followed a course and passed the exam at the Deutsche Bahn (DB).

Why tamping

Movie of a Unimat 08 -475 /4S

Unimat movie

.

Measurements and weigt

Length over buffers: 35.290 mm

Width: 3.000mm

Heigh over top rail: 3.743mm

Bogie pivot spacing (bogie 1<->2) 14.000mm

Bogie pivot spacing (b.2 <-> axle 5) 5.550mm

Axle spacing (axle 5<->6). 8.500mm

Track gauge: 1.435mm

Wheel diameter: 920mm

Weight: 113.100 kg

Lorem ipsum dolor sit amet, consectetur adipis cin elit.